The advantages and disadvantages of EDM

EDM (Electrical Discharge Machining) is an indispensable process in mold manufacturing and production. At present, EDM manufacturers have Agie, Charmilles, Mitsubishi, Sodick, Makino, Fanuc, Seibu, Chmer, etc. The main equipments include: Brass wire EDM machines, EDM forming machines, High-speed EDM small hole machines.

The main principle of EDM processing is to corrode the conductive workpieces through high-temperature discharge of electric sparks in order to meet the final processing requirements. EDM is the common equipment for machining complex precision parts, which has the following characters:

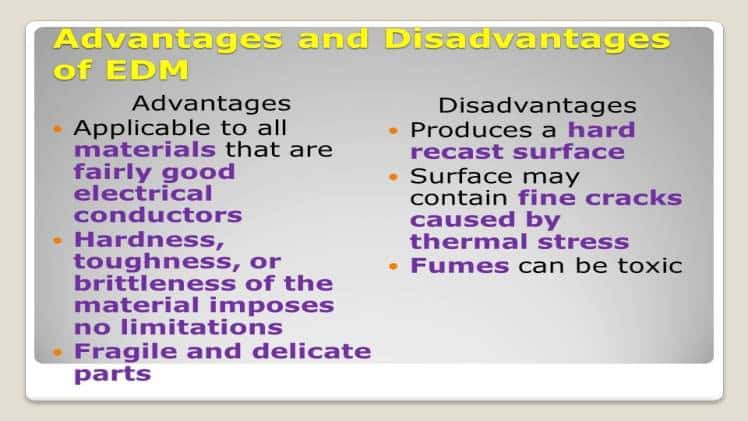

Suitable processing range: EDM machine tools can be used for processing various conductive materials, including: steel, copper, aluminum, titanium, alloy and other metals, and are also capable of processing super-hard materials such as carbide materials.

Wide range of applications: EDM machine tools are suitable for processing precision parts and complex shapes, especially in various industries such as aviation, automotive, medical, tool and mold manufacturing, etc.

Micron-level machining accuracy: EDM machine tools are distinguished in the industry by the high machining accuracy and the ability to machine precise and complex shapes on workpieces. They can control the tolerance range within microns and are especially suitable for use in high-precision and critical locations of workpieces..

Good surface finish: EDM machine tools can process workpieces with high surface finish, and can even achieve a mirror effect, reducing the need for later grinding and polishing.

Complex shapes: Brass wire EDM machine tools excel at cutting complex shapes and contours that would be difficult or impossible with traditional machining methods.

Upper and lower special-shaped surface processing: Brass wire EDM machine tools can accurately control the processing of the upper and lower special-shaped surfaces, which means workpieces with high-precision angles or tapered surfaces can be processed.

Non-contact machining: Unlike traditional machining methods, EDM is a non-contact machining. The brass wire, brass/copper electrode tubes, and graphite electrodes do not directly contact the workpieces, reducing the risk of wear or deformation of the workpieces.

Brass wires: The electrode wire of Brass wire EDM machine tools is a very thin brass wire. Common specifications: Ф0.15mm, Ф0.20mm, Ф0.25mm, Ф0.30mm. Brass wires are usually made of brass + zinc materials. Input “+” and “-” voltages on the brass wire and the workpiece respectively, and control the discharge energy and walking path through the program to process the required shape.

Reduce material waste: The cutting gap of Brass wire EDM machine tools is very narrow (usually within 0.30mm), which can minimize the waste of workpiece materials, especially in the processing of rare and precious metals, it can significantly reduce the cost of raw materials.

High automation: EDM machine tools are precisely controlled by CNC systems, and combined with automatic feeders, large brass wire spools and other components, they can achieve highly automated operations, making them more suitable for large-scale processing of complex and large workpieces.

Limitations of processing: Although EDM machine tools have the above advantages, they also have its limitations. Compared with other machining methods, their processing speed are slower and are only suitable for processing conductive workpiece materials.

When processing workpieces with EDM machine tools, for achieving the desired results, it should be work with experienced operators and CNC programmers. Specific processing parameters such as: brass wires specification selection, brass wires tension setting, discharge parameter setting, need to be tailored according to the material, thickness, processing accuracy and other requirements of the workpieces.