Restacking Pallets in the USA in 2025: How Smart Pallet Management Drives Supply Chain Efficiency

Restacking pallets in the USA in 2025 is no longer a minor warehouse task. It has become a strategic function that keeps freight compliant, shipments efficient, and operations running smoothly. As U.S. logistics networks become more synchronized and data-driven, restacking plays a crucial role in ensuring goods move faster, safer, and more cost-effectively.

From e-commerce fulfillment to cross-dock operations, restacking isn’t just about moving boxes — it’s about optimizing every square inch of load space and protecting product integrity across the supply chain.

What Is Restacking and When Is It Required in the Supply Chain?

Restacking pallets refers to the process of reorganizing, rebuilding, or redistributing palletized goods for better balance, compliance, or efficiency. It is frequently used when:

• Loads arrive in poor condition or improperly stacked

• Mixed freight must be separated or sorted

• Shipments need to be repalletized for LTL (less-than-truckload) delivery

• Import containers require compliance with domestic weight or safety standards

• Product damage risks must be minimized before final delivery

In 2025, U.S. warehouses, cross docks, and distribution centers rely on fast, precise restacking to keep freight moving through increasingly tight delivery windows.

Top Business Benefits of Professional Pallet Restacking Services

Choosing experienced restacking support is no longer optional for fast-moving supply chains. Businesses that invest in smart pallet restacking enjoy clear advantages:

• Improved safety compliance: Align with OSHA standards, DOT regulations, and load-balancing rules to reduce liability and risk.

• Optimized freight space: Restacked pallets fit better, travel safer, and maximize trailer or container capacity.

• Reduced damage and claims: Proper load configuration lowers the chance of shifting, tipping, or compression damage during transit.

• Faster dock-to-dock transfer: Speed up operations by ensuring pallets are ready for immediate reloading at transfer points.

For high-volume retailers, 3PLs, and importers, restacking is a cost-saving function that improves supply chain performance.

Freitty’s Approach to Smarter Pallet Restacking

Freitty leads the way in operational pallet services by offering intelligent restacking solutions across its U.S. network. With trained dock teams and real-time workflow management, Freitty’s system ensures:

• Freight is checked, corrected, and restacked to meet strict carrier or warehouse specs

• Damaged or unstable stacks are flagged and fixed fast

• Real-time communication between shipper, carrier, and receiver is maintained

With Freitty, restacking isn’t just reactive — it’s proactive. Their approach integrates smoothly with inbound scheduling, transloading, and outbound coordination to reduce bottlenecks and minimize costly delays.

Where Is Restacking Most Needed in U.S. Logistics?

In 2025, restacking has become a critical service in several core areas of U.S. freight:

• Cross dock facilities – for inbound consolidation and outbound route optimization

• Distribution centers – to sort mixed freight or correct shipments from overseas

• Import/export terminals – especially for freight arriving in overstacked, damaged, or misaligned condition

• LTL hubs – where dimensional accuracy affects pricing and routing

Wherever speed and precision are priorities, restacking services help eliminate friction and drive efficiency.

Choosing the Right Pallet Services Partner: Why Freitty.com Delivers

For companies operating nationally or regionally, Freitty.com offers a fast and reliable way to access professional restacking pallets services. Their network is designed for scale and speed, with features including:

• On-demand restacking across major U.S. freight corridors

• Staff trained in OSHA, DOT, and warehouse safety compliance

• Seamless integration with your TMS, ERP, or WMS platforms

• Load photography and digital reporting included in every service

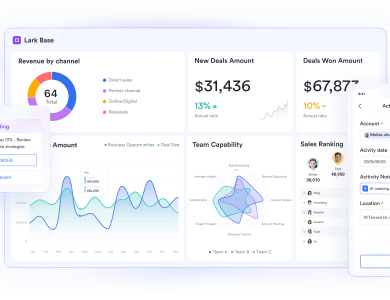

Freitty combines hands-on reliability with technology-first service. From the dock floor to digital dashboard, you know exactly how your freight is being handled.

The Future of Restacking in U.S. Warehousing Through 2025

As automation and AI continue to reshape warehouse operations, restacking will evolve from a reactive fix to a predictive advantage. Expect to see:

• AI-predictive load alerts before shipments arrive at the dock

• Robotic pallet restacking in high-volume terminals

• Digital compliance logs for every repalletized shipment

• Cross-dock integration that links restacking directly to outbound routing plans

In the fast-moving world of U.S. logistics, restacking pallets is no longer about fixing mistakes. It’s about building smarter, leaner, and more responsive supply chains — and with partners like Freitty, it’s already happening.